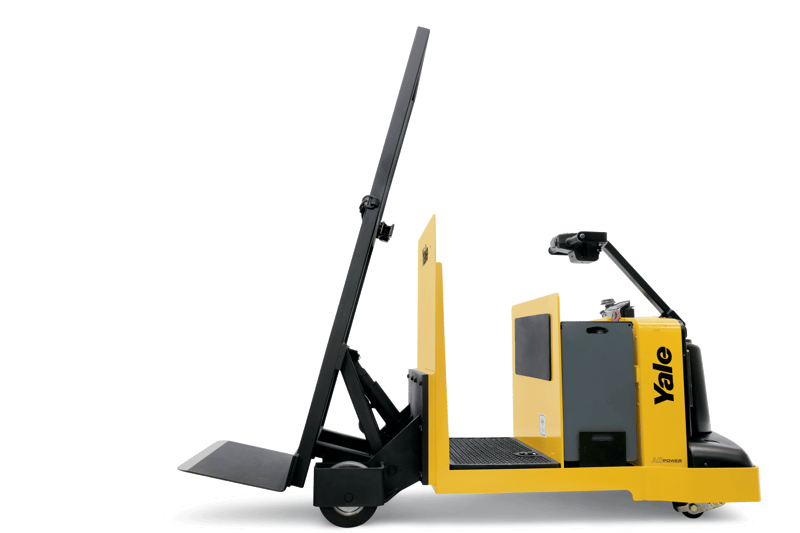

Yale MTR007-F Heavyweight Handler

Yale MTR007-F Heavyweight Handler Yale launches new solution for transport of flat-pack and odd-shaped items

Heavyweight Handler offers productivity advantages, labor savings compared to manual lifting crews and dolly transportation

To streamline the otherwise time-consuming and labor-intensive process of manually loading and unloading flat-pack and odd-shaped items, Yale Materials Handling Corporation introduces a new solution – the Yale MTR007-F Heavyweight Handler™. The Heavyweight Handler uses floor-level base support to slide under items and a tall, tilting load backrest to support them during transport.

Engineered to handle bulky, cumbersome items like furniture and household appliances, the Heavyweight Handler offers simple operation and enables operators to secure and maneuver even wedged or unbalanced product without manual intervention. An integrated load strap wraps around cargo for stability during transport.

“With a surge in flat-pack and odd-shaped items, warehouses are challenged to find an efficient way of transporting these items,” says Brad Long, Brand Manager, Yale Materials Handling Corporation. “The Heavyweight Handler is a solution tailored to the unique challenges of these tasks, capable of cutting unloading times in half and reducing labor requirements up to 40 percent.”

The Heavyweight Handler is the first fully commercialized solution for flat-pack and odd-shaped items – not just a one-off prototype. Operations can realize an estimated annual labor savings of nearly $75,000 per machine, based on 2020 warehouse worker fully burdened wage of $19.37 per hour, working 40 hours per week, 48 weeks per year.