TAB Wrapper Tornado compensates for uneven weight distribution on pallet

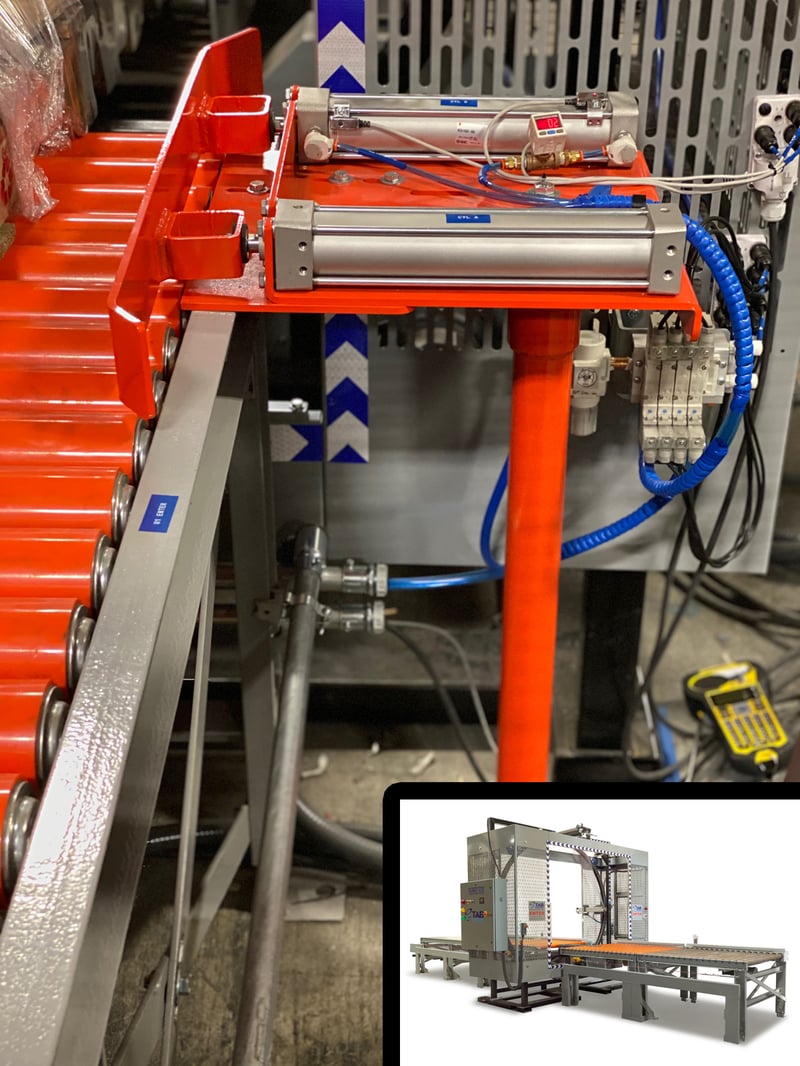

A new anti-fishtail device for orbital wrappers from packaging machinery manufacturer TAB Industries, LLC from Reading, Pa., automatically secures lightweight pallet loads and loads with uneven weight distribution in place to ensure smooth, consistent, automated pallet wrapping. Available as an option on the company’s fully automated TAB Wrapper Tornado Perfect Storm orbital wrapping systems, the anti-fishtail device automatically senses the presence of a pallet load on the infeed conveyor, centers it in the wrapping ring, and extends a steel bar to the pallet to keep it in place during the stretch wrapping process. The potential for light or unwieldy loads to rotate, slide, or fall from the pallet is eliminated.

Devised for wrapping thin gauge sheet metal, lightweight cardboard boxes, plastic parts, and other palletized loads, the anti-fishtail device offers an extra layer of certainty in the wrapping process when stretch wrapping loads weighing less than 100 lbs. With the new device, the TAB Wrapper Tornado Perfect Storm enables a single forklift operator to manage the entire pallet wrapping process without interruption when packaging lightweight pallet loads as well as much heavier pallet loads. The orbital wrapper automatically feeds, wraps, and discharges the pallet load encased in plastic in as little as 15 seconds.