Steele Solutions introduces SteeleTrax to maximize vertical space and enhance installation efficiency

New framing solution provides versatility, cost savings, and seamless integration with Steele Solutions’ platform systems.

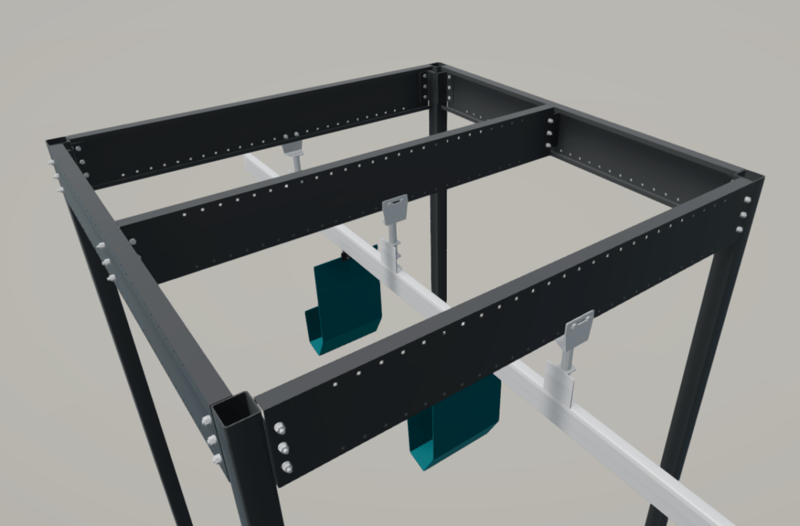

Steele Solutions Inc., a manufacturer of structural steel work/equipment platforms, material handling chutes, and public-safety security lockers, has introduced SteeleTrax, an innovative framing member designed to optimize vertical space utilization and improve installation efficiency in warehouse and distribution center operations.

SteeleTrax is a versatile and cost-effective solution for suspending essential equipment, such as pocket sorter conveyors, fire suppression systems, lighting, and conduit, from work platforms. With holes spaced 50mm in the center, SteeleTrax significantly reduces the need to manually drill holes in the framing during installation, lowering labor costs and shortening project timelines.

Noah Severin

“SteeleTrax enhances our turnkey approach by simplifying the integration of critical systems into our platform structures,” said Noah Severin, product manager at Steele Solutions. “Customers benefit from a seamless, high-quality solution that eliminates extra steps in the installation process and ensures compliance with industry standards.”

Key Features of SteeleTrax:

- Versatile Applications: Suitable for suspending a variety of mechanical, electrical, and plumbing (MEP) equipment, ensuring compliance with code requirements.

- Universal Design: Hole patterns enable consistent spacing and adaptability to meet project-specific needs.

- Reduced Installation Costs: Reduces the need for on-site drilling, saving time and minimizing labor expenses.

- U.S. Manufacturing: SteeleTrax is manufactured in the U.S. within Steele Solutions’ facilities, offering reliable domestic availability.

How SteeleTrax Works:

Designed to integrate seamlessly with Steele Solutions’ platform systems, SteeleTrax is available in profile depths ranging from 8-18” and thicknesses ranging from 14-gauge to 0.25”, with a maximum length of 20 feet. The hole pattern can also be customized to suit unique customer requirements, providing flexibility for various applications. SteeleTrax can be used in Steele Solutions’ open grid and decked platform structures.

Steele Solutions’ engineering team works closely with customers to develop the most efficient SteeleTrax system design that meets building codes and structural requirements, ensuring optimal performance and reliability.

Severin added, “By offering SteeleTrax, Steele Solutions provides customers with a reliable, all-in-one solution that enhances efficiency and streamlines installation processes without compromising quality.”