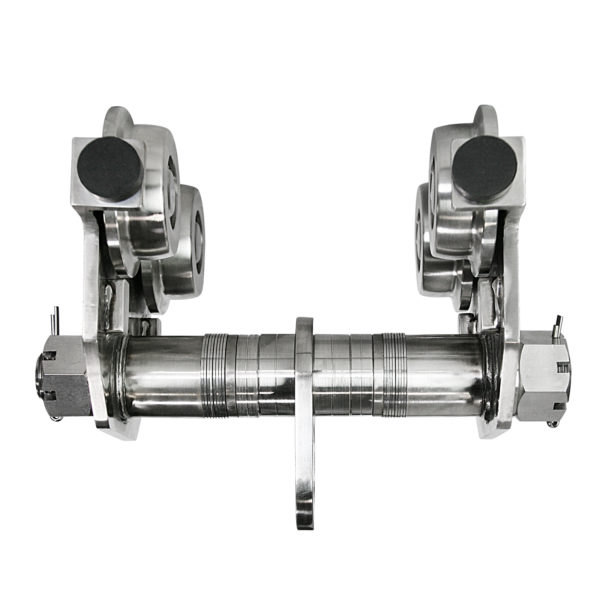

A 1 ton capacity version of OZ Lifting’s new stainless steel push beam trolley.

A 1 ton capacity version of OZ Lifting’s new stainless steel push beam trolley. OZ Lifting launches Stainless Steel Trolley

OZ Lifting Products LLC has launched the second in a new range of stainless-steel products—a push beam trolley.

The launch of the trolley, available in 1 ton and 2-ton capacities, follows the Winona, Minnesota-based manufacturer’s recent unveiling of a stainless steel chain hoist, designed for lifting and pulling. The products will commonly be purchased together as part of an overall system. Both items are in stock and available for delivery to OZ Lifting’s network of regional dealers. The fact that the product is only available in stainless-steel finish further accelerates shipment lead times.

Steve Napieralski, president at OZ Lifting, said: “Much fanfare greeted the launch of our [stainless steel] hoist, and our distributors have welcomed the rapid expansion of the range. The benefits of Grade 304 stainless steel are well known in and out of the industry, and we anticipate interest in individual units, hoists and trolleys, and multiples thereof, depending on the application.”

The trolley is adjusted using washers that are supplied with each shipment.

The push beam trolleys (they weigh 26.5 lbs. and 43 lbs. respectively) fit the most common I-, S- and W-beams; end-users have different types of beams depending on the construction requirements of the building or structure where the lifting equipment will be installed and employed. Each beam offers unique properties that ensure an appropriate level of support in each instance. The trolley is accordingly adjusted using washers that are supplied with each shipment, in addition to an owner’s manual and test certificate.

Napieralski suggested that all users adhere to a strict inspection and maintenance program, especially given that the product range is likely to be utilized in corrosive environments. However, the stainless steel trolley, like the hoist, does not require maintenance beyond that of a traditional steel product and will prove more durable owing to its inherent properties.

Additional features of the product, which are suited to use with manual or powered hoists, include an individual test certificate and serial number; stainless steel identity tag; anti-drop plate; and precision ball bearing trolley wheels. Again, the product meets a range of standards, including those of the American Society of Mechanical Engineers (ASME).

The trolley is designed for use in corrosive environments where the properties of stainless steel make it a preferred material. Napieralski revealed in conclusion that a third and final product in the stainless steel range—a beam clamp—will be put to market in due course.