On the Right Track: A look at JLG Compact Crawler Booms

JLG Compact crawler lifts feature low weight and non-marking tracks that allow operators to go more places around the job site.

These innovative lifts can climb slopes with ease thanks to their tracked wheel carriage, and their narrow chassis which allow for access through gates, yards, standard doorways, and public buildings. These unique features make compact crawler booms ideal for a wide variety of indoor and outdoor applications.

When choosing a compact crawler boom, there are several features that are key to meeting operators’ needs. Up-and-over reach is considered very important, as are, platform height, working height, and platform capacity. Environmental considerations are key for customers looking for a machine that can deliver clean, and quiet operation. Finally, tight workspaces and weight criteria, such as ground bearing pressure are important when working on sensitive floor surfaces.

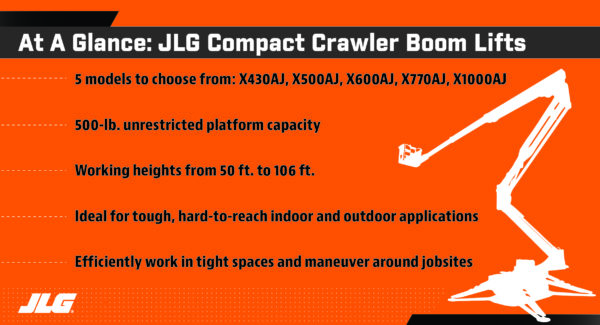

Randy Marzicola, director of business development at JLG, offers a closer look at the company’s compact crawler boom product offering, which boasts working heights from 50 ft. to 106 ft. and explains how these models are purpose-built to meet the market’s wants and needs.

What models of compact crawler booms does JLG offer?

Marzicola: JLG focuses its innovation in three core areas – productivity, safety, and technology. Our line of compact crawler booms offers innovative features that transform how facility and construction professionals complete work at height safer and more productively. JLG offers five compact crawler boom lifts: The X430AJ, X500AJ, X600AJ, X770AJ, and X1000AJ models.

The X430AJ offers a working height of 50 ft. and a best-in-class horizontal reach of 21 ft. 7 in. The unit is easy to transport and like all JLG models can be lifted by a forklift or crane, thanks to forklift pockets and lifting eyes.

The X430, X500, and X600AJ models fit through a single standard doorway, while the X770 and X1000AJ fit through a standard double doorway and offer outriggers that can be set in a narrow position and adjusted individually. This is a key feature of these larger working height class machines.

The latest addition to the JLG line – the X1000AJ – addressed the 100-ft. height class. It offers a 56 ft. vertical and 54-ft. horizontal outreach delivering a best-in-class working envelope. The Kubota® diesel power source is standard. With the electrification trend rapidly gaining acceptance, the 76V lithium-ion battery system is a popular choice. In fact, since this machine’s launch, we continue to experience tremendous growth in customer adoption of the clean and quiet performance of its lithium-ion battery power source. The X1000AJ comes with fully synthetic biodegradable hydraulic fluid for use in environmentally sensitive areas.

All models in the JLG range have a 500-lb. unrestricted platform capacity to complete a wide range of work at height.

What type of work are these booms used for?

Marzicola: Compact crawler booms are ideal for tough, hard-to-reach indoor and outdoor applications that require the operator to bring tools and materials to the work area, such as atriums, gymnasiums, arenas, auditoriums, airports, schools, and universities, as well as city, state, federal and military facilities. The versatility and ease of mobility of CCB’s make them ideal for jobs performed in hotels and convention centers by window washers, painters, maintenance professionals, electricians, and tree trimmers.

What are the benefits of a compact crawler boom compared to other types of boom lifts?

Marzicola: Compact crawler booms allow operators to go more places around the job site thanks to their low-weight design and non-marking tracks, key for many indoor and outdoor jobs. The compact footprint allows these machines to work in tight spaces, and their retractable non-marking tracks, along with being engineered with the JLG- patented platform disconnect system, makes them easy to maneuver through doorways.

What do operators need to know to operate a compact crawler boom?

Marzicola: JLG compact crawler booms are specifically designed to reach greater heights with increased machine flexibility, which enables operators to safely navigate a variety of workspaces.

First and foremost, it is important for any compact crawler operator to know that in order to operate this type of lift, they will require ANSI A92 compliant training. Manufacturers like JLG (and even select rental houses and associations) can help operators get certified. Some things operators will learn as part of the certification are regulations, safety hazards, proper operation and proper use of safety harnesses.

Compact crawler booms are fairly intuitive machines. They can be operated with ground controls or from the platform. Thanks to a handheld unit with a wire, operators can step outside the basket to operate it while walking next to the machine. This is extremely helpful when maneuvering it through tight areas.

Before operating a compact crawler lift, a workplace inspection should be completed that includes checking the work area for overhead hazards such as electric lines and bridge cranes. Floor surfaces should be checked for holes, bumps, drop-offs, obstructions, debris, concealed holes, and other potential hazards. Ground conditions should be evaluated to determine if they are able to support the maximum load shown on the decals located on the machine.

A machine inspection and functional checks should be completed prior to operation in accordance with the machine operation and safety manual. All machines should be serviced and maintained to the standards outlined in their operation and safety manual before use. This includes checking that all safety devices are operating properly and have not been modified and that all safety decals and instructional placards are in place.

Operators should not use the machine for any purpose other than positioning personnel, their tools, and equipment and should always use three points of contact when getting into and out of the basket. Proper PPE should always be worn, including a full-body harness with a lanyard attached to an authorized lanyard anchorage point. Only one lanyard should be attached per lanyard anchorage point.

For more information about JLG compact crawler boom lifts here.

About the Author:

Randy Marzicola

Randy is the Director of Business Development Development in Hagerstown, MD at JLG.