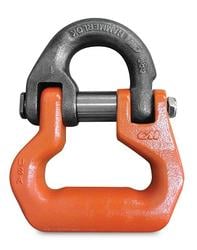

New CM Weblok- assembly features unique double load pin retention for optimal safety

Combining the industry-leading CM Hammerlok® coupling link with a CM web sling attachment, Columbus McKinnon Corporation, designer, manufacturer and marketer of material handling products, systems and services, introduces the CM Weblok™ Assembly for synthetic sling lifting applications.

Unlike any of its competitors, the CM Weblok features a double load pin retention system, using both traditional and bolt/lock nut retention. The unique design prevents the load from backing out during extreme use – delivering the highest degree of load securement on the market. This innovative product is part of Columbus McKinnon’s commitment to designing the safest and most efficient lifting equipment in the industry.

“The development of CM Weblok is a direct result of us listening to our customers,” said Troy Raines, Chain and Rigging Product Engineering Manager. “A team of CMCO application and product specialists, product managers and engineers worked closely with a major automotive manufacturer to address its safety concerns. As a result, Columbus McKinnon delivered a safe and viable solution when our competition couldn’t.”

Made in the USA, CM Weblok Assemblies are versatile and easy to use. Made of durable forged alloy steel, CM Webloks feature greater ductility, better fatigue life and higher ductile strength than cast parts. CM Weblok Assemblies have a 5:1 design factor and are 100 percent proof tested. They are designed to meet ASTM A9652 and WSTDA-RS1 standards.