New calibrated 3D machine vision inspection from Cognex

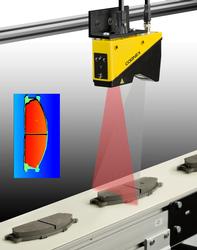

Cognex Corporation has announced the release of the new DS1000 3D laser profiling system. The system calibrates real-world units of measurement for inspections too difficult to perform with traditional two-dimensional machine vision. The new DS1000 3D sensor reads embossed or raised characters such as those on automobile tires and verifies the presence of low-contrast items in boxes or packages. In addition, it identifies surface defects and chips with low or no contrast, measures heights and tilts of components to determine misalignment and calculates volumes and dimensions for food portioning.

“The DS1000 3D sensor is factory-calibrated to provide real units of measurement with micron-level accuracy, making 3D applications easier to understand and deploy,” says Joerg Kuechen, Business Unit Manager for Cognex Vision Software. Kuechen adds, “Unlike other laser profilers, the DS1000 system is integrated with VisionPro® software, the most robust 3D vision tool set in the industry. With VisionPro, users can also add GigE cameras for 2D inspection tasks.” DS1000 is an integrated system; a Cognex proprietary high speed sensor and laser are both enclosed in an IP65-rated industrial housing.