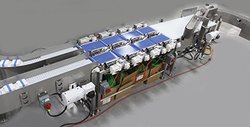

New 2:1 Servo Combiner by Multi-Conveyor

Multi-Conveyor recently built this 2:1 servo combiner to transport poly bags of food product that discharge from two customer supplied wrappers at 90 bags per minute. Products then combine into a single lane at 180 bags per minute for delivery to the customer’s secondary packaging equipment.

These stainless steel, sanitary constructed conveyor lines, for a caustic washdown application, are equipped with plastic side flexing and straight running chains – and polyester metering belts.

There are four servo metering belts in each lane that manipulate the position of each product to assist the powered side belt in merging the two lanes as show in these videos.

The system controls, as shown, utilizes ALLEN BRADLEY PowerFlex 525 VFD’s, Kinetix Ethernet servo drives, and CompactLogix PLC with embedded Ethernet and switches for machine communications and plant data acquisition – all housed in a NEMA 12 remote panel and all U.L. listed.

Line mounted devices are NEMA 4X including a pedestal mounted Panelview Plus HMI; epoxy coated servo motors with stainless steel servo rated gearboxes; photo eyes; local motor disconnects; and stainless steel terminal boxes.

The products shown are for demonstration purposes so you can see that the system is capable of handling a variety of sizes, shapes and weights.

Each servo merge system can be custom designed for individual applications based on the product, rates, environment, desired NEMA rating, safety category, customer specifications and available space.