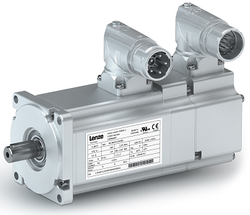

Lenze debuts cost effective MCM synchronous servo motors

Manufacturer of electrical and mechanical drives, motion control and automation technologies, Lenze Americas has launched a series of MCM synchronous servo motors that delivers intermediate-level dynamic performance. Scalable, modular Lenze MCM motors are easy to control and optimized for a range of positioning tasks, including robotics, packaging equipment and handling systems.

“Designed with an optimal torque and inertial mass ratio, our MCM servo motors give customers the precision they need in a compact and simple solution,” said Doug Burns, director of sales and marketing, Lenze. “MCM motors work in perfect harmony with Lenze inverters in positioning, return and any recurring motion sequences in the medium dynamic range.”

Modular MCM motors feature IP65-rated protection class housings with easily cleaned surfaces for food processing and other applications. Equipped with a robust resolver feedback system as a standard feature, the motors can be optionally supplied with multi-turn, sine-cosine encoders for high precision. SpeedTec connections with rotary connector boxes simplify and expedite installation, maintenance and replacement.

The Lenze MCM motor series is available in three sizes with power ratings of 0.27 to 3.35 Hp (0.2 to 2.5 kW). In conjunction with Lenze i700, 9400 and 8400 TopLine servo inverters, the economically efficient and powerful MCM motor drive solutions are capable of achieving torque ranges from 5.31 to 233.66 in-lbs. (0.6 to 26.4 Nm). Self-cooling MCM servo motors are optimized with spring-applied brakes, feedback systems and connections, and a comprehensive range of system cables for easy installation.

“Tailored for superior performance in positioning tasks requiring intermediate-level dynamics, MCM motors complement the Lenze portfolio, maximum precision requirements,” adds Burns.