JENvelt – vision enhanced laser tool

JENvelt – vision enhanced laser tool Intelligent laser control with new vision-enhanced laser tool

With its new vision-enhanced laser tool, Jenoptik is introducing an optical system for integration into laser production systems for micromaterials processing. This compact plug-and-play system is easy to integrate and caters for various process-related requirements in laser production. The system comprises a 2D galvo scanner, F-theta lens, and a camera with integrated image processing and intelligent software. System integrators benefit from shorter development times and a smart software solution, which enables users to get up and running quickly.

The centerpiece of the system is the “all-in-one” software, which combines scanner and laser control and image recognition with artificial intelligence. The software maps production projects, and monitors the ongoing process while ensuring that the data obtained is evaluated and fed back into the control system: When a production order is set up, optical markers are defined to ensure the laser spot is accurately positioned, enabling the device to “check” and “compare” the position of the workpiece in relation to the laser spot and then to reposition it if necessary. This is done with a positioning and repeat accuracy of up to 10 micrometer. The laser spot is positioned precisely at the predefined location regardless of the component’s geometric and position tolerances.

This makes cumbersome clamping fixtures obsolete or, if the process requires them to be used, makes them easier to implement. The process is particularly beneficial when processing workpieces that are manufactured with comparatively high tolerances, such as injection-molded plastic parts. Increased production yield from the first component onwards improves the production result and productivity alike.

JENvelt – vision enhanced laser tool

Calibration at the push of a button ensures machinery can be converted flexibly and quickly, e. g. in the case of varying production orders. Consistently high levels of precision and reproducible results make production more efficient.

From the fourth quarter of 2019, Jenoptik will be offering two different versions of the vision-enhanced laser tool: a cost-efficient eco variant and a high-performance variant, targeted at speed and accuracy.

Test installations and tailored application advice are available to help users determine the suitable hardware and the relevant optical system can be determined. Customers also benefit from high-quality coated lenses, calibrated hardware and prefabricated software modules relevant to the respective application.

F-Theta bundle for quick integration

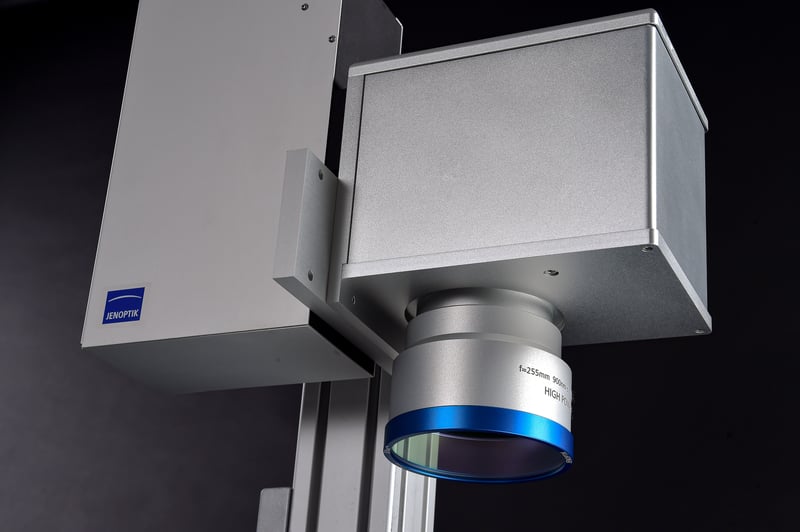

Jenoptik has a F-theta bundle available for integration into laser production systems that need to function without image processing due to the process. This easy-to-integrate optical system solution combines an F-theta lens from the JENarTM or SilverlineTM lens range with a compatible 2D galvo laser scanner. The bundle can be used at wavelengths of 355, 515 – 532, and 1030 – 1080 nanometers with apertures of 15, 20, 30, and 50 millimeters and laser applications into the kilowatt range.

Jenoptik provides the F-theta bundle in the following standard configurations:

- Ftheta bundle “High-performance IR”, 1030 – 1080 nanometers, with an aperture of 20 and a focal length of 255 millimeters

- Ftheta bundle “High-performance UV”, 355 nanometers, with an aperture of 15 and a focal length of 100 millimeters

- Ftheta bundle “Economic IR”, 1030 – 1080 nanometers, with an aperture of 20 and a focal length of 420 millimeters

- Ftheta bundle “High-performance GR”, 515 – 532 nanometers, with an aperture of 15 and a focal length of 255 millimeters.

Customers with special requirements can individually combine Jenoptik’s own F-theta lenses with different laser scanners for their application. In terms of laser scanners, Jenoptik has devices qualified for a wide range of applications, allowing them to react flexibly to customer requirements.

Jenoptik supports all hardware combinations with system components that are precisely tuned to one another and calibrated. This helps to minimize the incidence of imaging errors. The F-theta bundle is designed for laser material processing, such as engraving, drilling, marking, and welding of plastics and metal.