Columbus McKinnon to exhibit Lifting and Motion Control Products at AISTech 2019

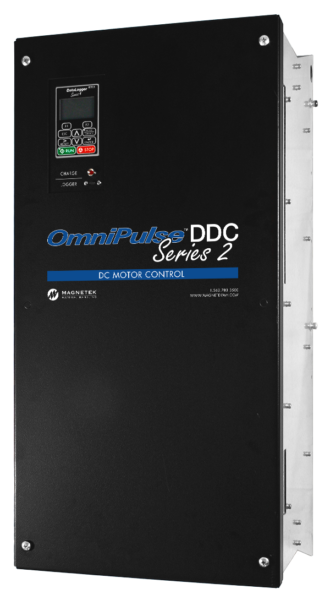

Columbus McKinnon Corporation, a designer and manufacturer of motion control products, technologies, and services for material handling, will be exhibiting its range of crane solutions products at the 2019 AISTech Iron & Steel Technology Conference and Exposition being held in Pittsburgh, May 6-9, at the David L. Lawrence Convention Center. Visitors to booth 919 will have the opportunity to view the Company’s advanced wire rope hoists, variable frequency drives, mill duty brakes, radio remote controls, and cable reels. Additionally, the Company will be exhibiting their Magnetek brand OmniPulse™ DDC Series 2 drive and a hands-on IMPULSE®·VG+ Series 4 drive demo that showcases specialty features including Load Summing, Anti-Shock, Hoist Synchronization, Weight Measurement II, and advanced system diagnostics.

“From Magnetek’s smart crane controls to Yale® electric wire rope hoists, all crane system components can be sourced through Columbus McKinnon,” said Dan Beilfuss, director of material handling and North America wire rope hoists. “With our technological expertise and innovative power and motion control systems, we work every day to increase the productivity, safety, and uptime in our customer’s facilities.”

The OmniPulse DDC Series 2 drive improves the performance, safety, and reliability of DC-operated material handling systems and has a flexible design, making front wired components easily accessible. OmniPulse DDC Series 2 also features the DataLogger Series 4 keypad, which makes troubleshooting simple and allows for configuration of drives without switching between two devices to log or modify parameters.

Precision engineered for optimal performance, Yale® YK™ wire rope hoists are available as monorail, double girder, and base mount units. Yale YK is built for reliable operation, high efficiency, and long service life in a compact, easy-to-maintain design. Operators, crane manufacturers, and system manufacturers can benefit from the hoist’s modular system that allows for configuration of the hoist and crane system to exact application needs.

Attendees will be able to operate the hands-on hoist demo that showcases many crane control safety and productivity features. The demo features custom Weight Measurement System drive software, consisting of both Load Summing and Weight Measurement II functions. These features allow multiple hoists to measure the load on each hook without a load cell, add the weights together, and prevent an additive overload of the crane structure. Hoist Synchronization, which allows for multiple hoists to be operated in tandem with precision down to a fraction of an inch, will also be showcased. Operation and diagnostic information is displayed on an interactive HMI touch-screen, unlocking virtually unlimited potential for monitoring drives on a wired or wireless network.

A selection of radio remote control products and a mill duty brake will also be on display. Rugged, reliable radio remote control systems provide equipment operators with better positioning for job visibility and safety, data feedback, and extended product lives. Advanced design features, combined with fabricated steel construction, make Magnetek brakes suitable for applications requiring braking with minimal maintenance and downtime.

Finally, Columbus McKinnon will be showcasing Magnetek brand mill duty cable reels, superior solutions to effectively and compactly manage large lengths of cable. Mill duty reels, available in multiple sizes, are ideal for heavy-duty applications in harsh environments, such as mills and foundries, and high-duty cycles and speeds.

Product specialists will be on hand to answer questions, demonstrate products, and discuss project solutions, including automation systems that directly improve safety for equipment operators and work environments.