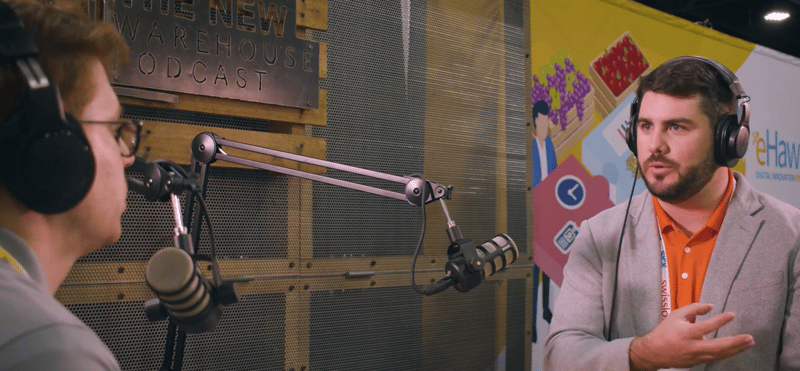

Episode 331: Mujin at MODEX 2022

Welcome to today’s episode of The New Warehouse, where we welcome Josh Cloer, Director of Sales at Mujin Corp. Mujin operates globally but is relatively new to the U.S. market. They specialize in robotics technology, specifically in the warehouse space, and believe in robots taking on dirty and dangerous tasks so humans can perform more creative work. In this episode, Josh and Kevin discuss the MujinController and how far robotics has come in advancing warehouse operations.

Key Takeaways

- The MujinController takes a different approach to deploying robotics. Mujin’s new controller allows for easier deployment of robotics in factories by using software to plan and manage movement instead of programming the robots manually. This approach allows for greater flexibility and accuracy in robot movement, reducing the variability that environmental factors can cause.

- Mujin offers a complete technology package that includes the controller, advanced gripping, and 3D vision technology to provide solutions for palletizing, de-palletizing, and other material handling requirements. Josh shares how Mujin works with all the major robotics companies, and the four brands in action at their booth are busy performing various tasks you would see in a typical warehouse.

- Robotics have been excellent for picking and packing pallets and cases when variability is limited. Building mixed-case pallets have often been a challenge, but Mujin has solved this problem, and their technology is able to build mixed-case pallets on the fly with no programming. Josh explains how the robot can “play Tetris” by putting cases to the side, tracking the cases, and using a digital twin visualization of the environment to get smarter. This capability is a massive advantage for distribution centers sending products to smaller retail locations.