Midland Pallet Trucks urges warehousing industry not to overlook human element during robotic revolution

As the robotic revolution continues to gain momentum in the UK’s warehousing and logistic sectors, Midland Pallet Trucks, a provider of high-quality lifting equipment including pallet trucks, manual stacker trucks and lift tables, is urging managers not to forget their human workers when investing in new robotic technologies.

With Covid-19 being something of a turning point for the UK warehousing sector due to the added demand placed on the industry, many warehouse owners have been looking into ways to automate certain tasks to improve efficiency and streamline processes to maximize productivity.

With the demand for good quality warehousing space hitting an all-time high due to the global pandemic and Brexit, the ability to move goods quickly through warehouses and distribution hubs is essential for businesses working within the sector to be as profitable as possible.

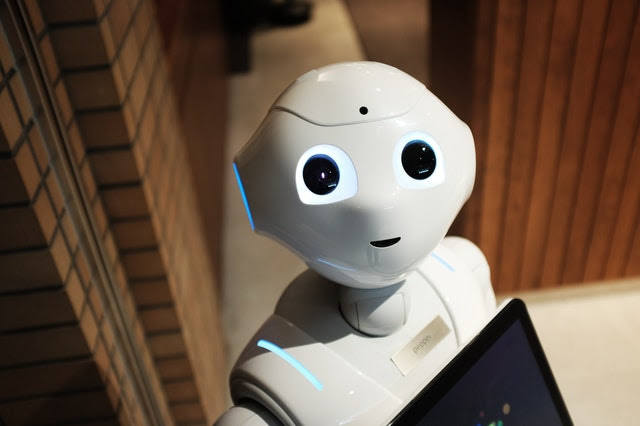

Seen as the future of logistics and warehousing, robotic technology is set to allow later ordering cut-off times and next-day delivery subscription services. It’s likely that certain roles usually undertaken by humans will be carried out by robot control systems that are capable of working at the same rate of productivity 24/7 without the need for breaks or the risk of workplace injury.

According to a recent report, it has been estimated that automated robotics goods-to-person order-picking can increase efficiency by an incredible 84% which will, in turn, save over 58% on labor costs as well as increasing picking performance from 100 picks per hour to over 600.

However, as many members of the warehousing industry keep their focus firmly on robotics and efficiency improvements, Phil Chesworth, Managing Director of Midland Pallet Trucks is urging those working within the sector to consider the bigger picture and not forget about the needs of the people that will still be a necessary part of warehouses of the future.

″There’s no denying that automation and robotics have a significant part to play in the future of the warehousing sector, but we mustn’t lose sight of those people that will still be working in the industry alongside this brand-new technology.

“Just as robots need repairs and maintenance, humans need certain pieces of equipment to protect them against the risk of injury. When planning new warehouse layouts and labor needs, it is important that lift equipment for human workers isn’t forgotten as they will still be an integral part of the fabric of any warehouse.″