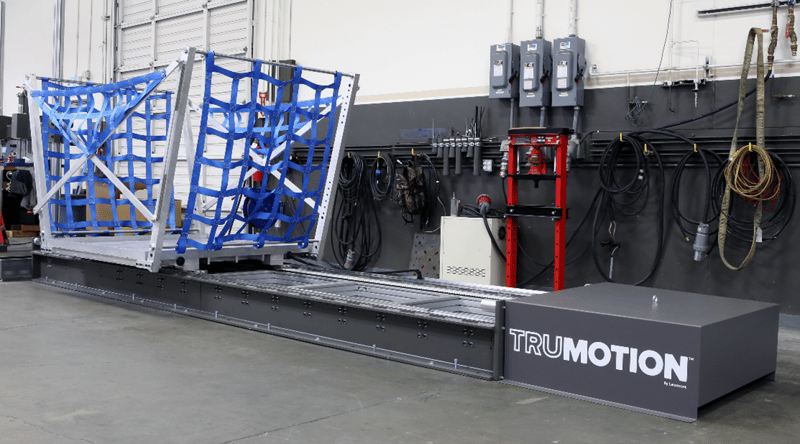

The Lansmont TruMotion Sled is used to simulate the dynamic horizontal stresses experienced by unitized loads when transport vehicles brake and turn.

The Lansmont TruMotion Sled is used to simulate the dynamic horizontal stresses experienced by unitized loads when transport vehicles brake and turn. Lansmont Corporation donates product and packaging testing technology to MSU

Lansmont Corporation, part of the Physical Properties Testers (PPT) Group, is extending its investment in packaging durability testing and research by donating some of its test and measurement technologies to the Michigan State University (MSU) School of Packaging.

Lansmont holds strong historical ties with the university, as the company was established in 1971 – in part – by a number of MSU School of Packaging alumni.

Today Lansmont is world-renowned for its shock and vibration measurement and testing technology, counting leading companies, government laboratories, and educational institutions among its customers.

“The School of Packaging is pleased to extend our partnership with Lansmont through this generous gift,” said Matthew Daum, Ph.D., MSU School of Packaging director and assistant dean of corporate relations and strategy for the College of Agriculture and Natural Resources (CANR).

“New and updated equipment ensures our students have the best hands-on learning experiences with industry-leading equipment. MSU has a long history of distribution packaging thought leadership, and this gift helps ensure we maintain a strong program.”

With damage prevention at the core of Lansmont’s ethos, the in-kind equipment donations will include a TruMotion Acceleration Sled system, an updated data acquisition system, vibration table controller and software, a shock table, and controller, as well as next-generation SAVER units.

The SAVER environmental data recorders help companies measure what shock, impact, and vibration levels a product or package is exposed to in the supply chain. That data then allows for the assessment and characterization of both the dynamic and atmospheric hazards present within transportation and in-use environments.

Being part of the PPT Group has enabled Lansmont to further extend its donation by including other group testers such as Mecmesin’s bench-top compression and tensile testing equipment, as well as Alluris torque testing equipment. This provides students with an all-around testing solution that is rather unique in the area of physical properties testing solutions.

“MSU’s School of Packaging is a vital building block in the world of packaging testing,” says John Page, PPT Group Managing Director. “For us to facilitate the learning and research that takes place at this institution is both a privilege and a sure investment in the study of packaging dynamics.”

The PPT Group is a family of brands, which includes Lansmont, who are experts in the design and production of physical properties testing solutions for quality control.

(L-R) Rod Ansari – PPT Americas Director of Sales and Operations, Eric Joneson – Lansmont VP of Technology, Bart Feys – Lansmont Business Development Manager, and Matthew Daum – Ph.D., MSU School of Packaging director and assistant dean of corporate relations and strategy for the College of Agriculture and Natural Resources.

Lansmont’s ties to East Lansing

Lansmont’s support of packaging research and the development of future packaging professionals is clearly not the company’s only tie to MSU.

Around 1968 under the guidance of MSU School of Packaging Director James Goff, Ph.D., the school partnered with Monterey Research Labs (MRL) in Monterey, California, to test real-world products using what was called the Fragility Assessment Theory and Test Procedure — originally developed Bob Newton, Ph.D., of the Naval Post Graduate School. This procedure allowed for an engineering approach for defining a product’s fragility, or ruggedness. Establishing those product durability characteristics would allow Packaging designers to subsequently establish protective packaging performance requirements – all quantifiable metrics.

Using an IMPAC shock machine on consignment from MRL, a number of MSU graduate students, including Ed Church, Ken Horiszny, and Dennis Young, performed extensive shock testing of different products to help validate Dr. Newton’s theory. Ultimately, their positive results led to the establishment of the Lansmont Corporation and the proliferation of shock test systems throughout the world. The company was named LANSMONT, combining LANSing and MONTerey.

Lansmont Corporation was formally established in 1971 by four MSU School of Packaging alumni. Pictured at the MSU Packaging Building are (left to right): Ed Church and Ken Horiszny, both MSU graduate students at the time; Bill Kipp and Frank Bresk, MSU packaging alumni working for Monterey Research Labs at the time; and on the far right is Dennis Young, MSU grad student. Church, Horiszny, Kipp and Bresk are the four legal founders of the Lansmont Company. The shock machine on the left was the original IMPAC test system consigned from MRL.

“This gift is a prime example of MSU School of Packaging alumni giving back, helping out tomorrow’s packaging professionals, and investing in the future of the packaging industry,” Daum said. “We are truly amazed and grateful for the continued support and far-reaching network of our MSU packaging family.”