Integrating mobile robots from multiple vendors

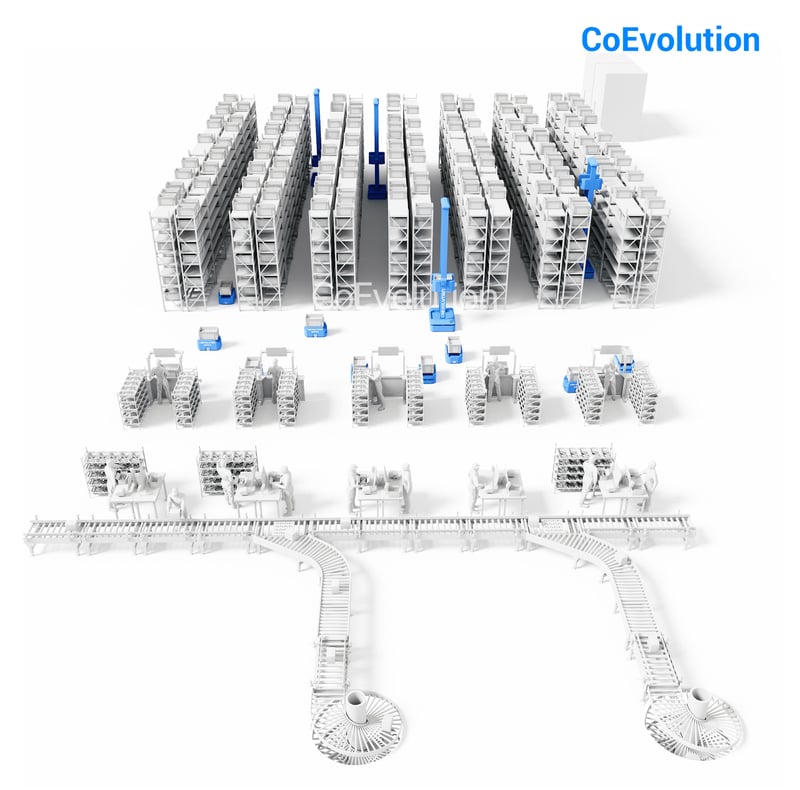

Creating heterogeneous fleets of mobile robots by integrating products from different vendors is the next step in warehouse automation. CoEvolution is bringing this technology to the US.

CoEvolution, a provider of intelligent logistics solutions, has announced it will soon be entering the US market with a solution that enables the creation of fleets of mobile robots from multiple providers by integrating with and talking directly to the robots.

The CoEvolution solution does not simply just connect existing robot systems, it also offers a unified robot control system meaning it can talk directly to robots from any provider. Essentially, it functions as a ‘universal translator’: an open platform that can integrate with any mobile robot. The technology allows logistics companies and warehouse managers to build unique warehouse automation solutions tailored to their specific needs.

This capability has been enabled by two important developments. First, the mobile robot market has reached a high level of maturity, meaning there is now a wide range of cheap, reliable, and capable mobile robots easily available. Second, recent major advances in software planning technology have broken the barriers to the coordination of multiple robots from different fleets in a warehouse environment. These advances have involved taking video game technology that enables the planning of movements of multiple agents and applying it to real-world fleets of heterogeneous robots.

Lijun Zhu

Lijun Zhu, CEO of CoEvolution, says: “Because of the US market’s ever-growing demand for e-commerce and the ongoing labor shortage, many logistics companies are starting to think about implementing full workflow automation. This requires a combination of specialist robots from different providers. It is a difficult challenge to solve, but CoEvolution has invested heavily in this technology.

“We have developed strong expertise in helping logistics companies to solve the problem of creating and coordinating heterogeneous fleets of robots from diverse providers. Effectively, we fulfill the role of both software developer and systems integrator for warehouse automation solutions. The results speak for themselves. One recent customer in South Korea – Yunda Express Korea – has doubled its storage capacity and reduced labor costs by 40%.

“As an Asian company, we’ve got experience at working in some particularly challenging and fast-moving Asian markets. Now we are bringing that expertise to the US. We are currently looking for on-the-ground business partners in the US. And we’ll be attending the ProMat show in Chicago in March 2023. We hope to meet you there!”