Hyster-Yale Materials Handling announces Fourth Quarter and Full Year 2018 Results

Hyster-Yale Materials Handling, Inc. today announced consolidated revenues of $837.7 million and a consolidated net loss of $1.2 million, or $0.07 per share, for the fourth quarter of 2018 compared with consolidated revenues of $795.5 million and a consolidated net loss of $2.4 million, or $0.15 per share, for the fourth quarter of 2017.

Full-year 2018 lift truck shipments increased to approximately 101,900 units from approximately 93,400 units in 2017, and consolidated revenues increased to $3.2 billion compared with $2.9 billion in 2017. Consolidated operating profit decreased to $38.8 million in 2018 from $74.1 million in 2017. The Americas implemented price increases during the first half of the year and a tariff surcharge in November 2018 to offset material cost inflation driven by U.S. aluminum and steel tariffs and increased U.S. tariffs on components and lift trucks imported from China. However, operating results continued to reflect the lag of a $25.7 million shortfall in the full-year 2018 results between fully realizing those price increases and when the tariffs and material cost increases were first realized. Consolidated net income was $34.7 million, or $2.09 per diluted share, for the year ended December 31, 2018 compared with consolidated net income of $48.6 million, or $2.94 per diluted share, for the year ended December 31, 2017.

The 2017 fourth quarter and full year consolidated results included a net expense of $18.4 million related to the 2017 U.S. tax reform legislation. Excluding the net impact of this legislation, Adjusted income was $16.0 million, or $0.97 per diluted share, for the fourth quarter of 2017 and $67.0 million, or $4.06 per diluted share, for the 2017 full year. For a reconciliation from GAAP results to the non-GAAP results, see page 8.

At December 31, 2018, the Company’s cash position was $83.7 million and debt was $301.5 million compared with cash of $220.1 million and debt of $290.7 million as of December 31, 2017. The decrease in cash and increase in debt were primarily driven by the acquisition of Maximal in the second quarter of 2018 and an increased investment in working capital.

For the 2018 full year, the Company’s consolidated cash flow before financing activities was a negative $43.3 million, which was comprised of net cash provided by operating activities of $67.6 million less net cash used for investing activities of $110.9 million, including $77.9 million for the acquisition of Maximal, net of cash acquired. For the 2017 full year, the Company generated consolidated cash flow before financing activities of $117.4 million, which was comprised of net cash provided by operating activities of $164.7 million less net cash used for investing activities of $47.3 million.

Segment Financial Results

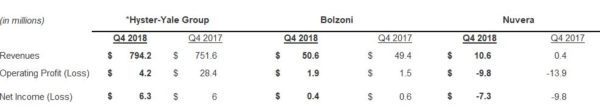

Summary segment results for the Company’s three business segments were as follows for the fourth quarter of 2018 and 2017:

*For purposes of this release, Hyster-Yale Group refers to the Company’s Lift Truck business, Bolzoni is the Attachment business and Nuvera is the Fuel Cell business.

The following is a summary of Hyster-Yale Group unit shipments, bookings and backlog for the 2018 and 2017 fourth quarters and the 2018 third quarter.

|

($ in millions) |

Fourth |

Third |

Fourth |

||

|

Unit Shipments |

27,700 |

25,600 |

25,900 |

||

|

Unit Bookings |

29,200 |

26,200 |

24,600 |

||

|

Unit Bookings $ value |

$690 |

$560 |

$615 |

||

|

Unit Backlog |

43,900 |

42,300 |

33,800 |

||

|

Unit Backlog $ value |

$1,190 |

$1,090 |

$860 |

In the 2018 fourth quarter, the average sales price per unit in backlog increased over the prior year and the 2018 third quarter as a result of an increase in shipments of lower-priced units during the current quarter, while shipments of higher-priced units, including Big Trucks, were lower primarily because of supplier parts shortages.

Americas Results

Revenues in the Americas segment, which includes the North America, Latin America and Brazil markets, increased to $516.1 million in the fourth quarter of 2018 from $487.4 million in the fourth quarter of 2017. This increase was primarily the result of price increases implemented to offset higher material costs and tariffs, other revenues generated from the recognition of revenue that had previously been deferred on fuel cell battery box replacement (“BBR”) units sold to third parties by the Americas and from higher remarketing services, as well as an increase in parts sales. These improvements were partially offset by modestly lower unit volumes. Unit shipments decreased by approximately 600 units from the prior year fourth quarter, driven by fewer shipments of higher-priced Class 2 electric trucks and Class 5 Big Trucks in the North America market, partly offset by an increase in shipments in Brazil as that market continues to recover. Backlog in the Americas increased 6,700 units over the prior year fourth quarter and 2,000 units over the 2018 third quarter as a result of supplier issues, prudent production scheduling and higher bookings and backlog in Brazil.

Despite an increase in revenues, operating profit in the Americas, which includes corporate headquarters results, decreased to $4.0 million in the fourth quarter of 2018 from $23.7 million in the prior year quarter. Operating profit decreased due to both lower gross profit and an increase in operating expenses. The decrease in gross profit was primarily the result of material and freight cost inflation including import tariffs, net of price increases, manufacturing inefficiencies caused by supplier parts shortages and an increase in warranty expense. The Americas implemented price increases during the first half of the year and a tariff surcharge in November 2018 to offset material cost inflation and aluminum and steel tariffs, but the fourth-quarter operating results continued to reflect a $5.7 million shortfall resulting from the lag between the implementation of the price increases and when those price increases are fully realized in unit revenues. Operating expenses increased mainly due to an increase in incentive compensation resulting from an adjustment for the net impact of tariffs on full-year 2018 results, additional investments in the expansion of Hyster-Yale Group’s industry-focused sales and marketing teams and increased product development costs to support a planned major upgrade to one of the Company’s core product platforms.

EMEA Results

Revenues for the EMEA segment, which includes operations in the Europe, Middle East and Africa markets, decreased to $207.7 million in the fourth quarter of 2018 from $215.2 million in the fourth quarter of 2017. Despite an increase in unit volumes, revenues declined because an increase in revenues on lower-priced Class 3 units did not offset the effect of lower sales volumes of higher-priced Class 1, Class 2 and Class 5 trucks, including Big Trucks, compared with the prior year. Backlog in EMEA increased approximately 2,000 units over the 2017 fourth quarter and 200 units over the 2018 third quarter. Unfavorable currency movements from the translation of sales into U.S. dollars partly offset by higher parts sales and price increases, also contributed to the revenue decline.

EMEA had operating profit of $4.2 million in the fourth quarter of 2018 compared with $5.3 million in the fourth quarter of 2017. The impact of favorable currency movements of $2.8 million and price increases, net of material cost inflation, were more than offset by decreased volumes of higher-value lift trucks, specifically Big Trucks because of ongoing parts shortages, as well as manufacturing inefficiencies caused by supplier constraints and national labor-related strike days at the Company’s Nijmegen plant. A modest increase in operating expenses primarily due to higher incentive compensation also contributed to the decline in operating profit.

JAPIC Results

Revenues in the JAPIC segment, which includes operations in the Asia and Pacific markets, including China, as well as results from Hyster-Yale Maximal since it was acquired in June 2018, increased to $70.4 million in the fourth quarter of 2018 from $49.0 million in the fourth quarter of 2017. The increase was driven by the acquisition of Hyster-Yale Maximal, which contributed revenues of $22.7 million generated by shipments of approximately 1,600 units.

JAPIC generated an operating loss of $4.0 million in the fourth quarter of 2018 compared with an operating loss of $0.6 million in the fourth quarter of 2017. Included in the 2018 results was an operating loss at Hyster-Yale Maximal of $0.8 million, which included $1.0 of amortization expense for the write-up of acquired assets to fair market value. Excluding the impact of Hyster-Yale Maximal, JAPIC’s operating results declined primarily as a result of increased costs to expand JAPIC’s sales and marketing teams and higher product development costs to support the Company’s growth initiatives, as well as a product mix shift and an increase in material and freight costs.

Bolzoni Results

During the fourth quarter of 2018, Bolzoni’s revenue increased to $50.6 million from $49.4 million in 2017 primarily due to higher volumes in the EMEA market, partly offset by unfavorable currency movements. Bolzoni’s operating profit increased from the prior year quarter mainly as a result of improved margins on products sold, partially offset by higher operating expenses from the continued implementation of strategic programs to increase Bolzoni’s presence in North America.

Nuvera Results

During the fourth quarter of 2018, Nuvera recognized revenues that had previously been deferred on fuel cell BBRs sold to Hyster-Yale Group, which are eliminated in consolidation. Revenue on these units had been deferred due to the inability to estimate future warranty costs because the BBRs are new technology and the design of the product continues to evolve. The Company determined that sufficient data was available in the 2018 fourth quarter to reasonably estimate all of the future costs related to the sale of BBR units, including warranty costs.

Nuvera’s 2018 fourth-quarter operating loss decreased compared with the prior year quarter mainly as a result of the absence of a $4.9 million asset impairment charge taken in 2017 and product development funding received from third-party customers. This improvement was partially offset by the recognition of higher warranty expense, higher employee-related costs and an increase in product development and production start-up costs related to Nuvera’s third-party development agreements.

Investor Perspective

Hyster-Yale is currently undertaking the largest set of transformational programs in the Company’s history. These programs are expected to have a very significant impact on Hyster-Yale’s competitiveness, market position and economic performance over the next three to five years.

For some time, the Company has been focused on six strategic initiatives:

- Provide the lowest cost of ownership, while enhancing productivity for customers.

- Be the leader in the delivery of industry- and customer-focused solutions.

- Be the leader in independent distribution.

- Grow in emerging markets.

- Be the leader in the attachments business.

- Be a leader in fuel cells and their applications.

The projects required to execute fully on these initiatives have been, in general, initiated over the last several years and many are now moving toward completion. Further, many of the projects supporting these strategic initiatives are inter-related and succeeding in one will foster success in others. In total, these projects have required significant up-front expense and capital expenditure investment. The projects cover a very broad range of Hyster-Yale activities, including product development, supply chain, IT, manufacturing, sales and marketing for each of the Company’s three major businesses, Hyster-Yale Group, Bolzoni and Nuvera.

Over the course of 2017 and 2018, these investments, both expense and capital, increased significantly. Further, investment will continue to be made in 2019 and then generally remain at those levels for the next several years. The return from these investments has started to be realized and is expected to increase over the course of Hyster-Yale’s five-year planning period. In this context, Hyster-Yale Group income is expected to improve in 2019 over 2018, but results in the first half of the year are expected to be lower than the first half of 2018, and then improve in the second half. Beginning in 2020, further improved results are expected with significant increases through 2023. Hyster-Yale Group’s objective is to meet its target of 7% operating profit in this period assuming reasonable market conditions continue. Likewise, Bolzoni’s results are expected to improve in 2019 and in the following years with a target of 7% operating profit. Nuvera’s results are expected to improve moderately in the first three quarters of 2019 with a break-even target for both the fourth quarter and for the 2020 full year. Further, significantly improved earnings are expected at Nuvera in the 2021 to 2023 time period. At each of these three businesses, the investments being undertaken are expected to lead to increased operating profit through higher volume, decreased product costs and improved pricing, partially offset by a higher level of operating expense. Overall, 2019 consolidated operating profit is expected to increase significantly, with the improvement coming in the second half of the year.

At Hyster-Yale Group, product programs are expected to lay the groundwork for enhanced market position by providing lower cost of ownership and enhanced productivity for the Company’s customers. At the core of these programs is a new set of modular and scalable product families covering both internal combustion engine and electric trucks, which will provide customers with enhanced flexibility for meeting their application needs combined with the benefit of lowest total cost of ownership. Implementation of these programs are expected to begin in 2020 with the introduction of a new range of counterbalanced trucks, with this range being expanded comprehensively through 2025 to include larger counterbalanced capacities, Big Trucks and warehouse trucks. A further major initiative in product offerings will come from the introduction of trucks manufactured by Hyster-Yale Maximal, Hyster-Yale Group’s new majority-owned joint venture in China. A line of trucks from Hyster-Yale Maximal has been engineered to provide high quality and reliable utility trucks for global markets and standard trucks for the Chinese market. In addition, Hyster-Yale Maximal and Hyster-Yale Group’s partner in India is expected to expand local production of larger trucks. Further, in early 2019, a new end rider was launched in the North America market, and a new Reach Truck for North America, as well as lower-cost Class 3 walkie and stacker global products are expected to be introduced later in the year. Rough terrain and electrified Big Truck products are being added to the product line-up. To further enhance productivity for customers, Hyster-Yale Group is developing automation solutions for warehouse trucks, initially in combination with industry partners. Some of these products are already in the market today, but new solutions and customers are expected to be developed progressively over the next several years. Hyster-Yale Group continues to expand sales of telemetry products and new generations of lift trucks will offer a fully integrated telematics solution. Finally, Hyster-Yale Group anticipates introducing new fuel cell BBRs for Class 1, 2 and 3 forklift trucks over the next two years that are expected to move the fuel cell BBR business to break-even in 2020.

The introduction of these new products will lead to significant changes in supply chain sourcing and in the Company’s various manufacturing facilities around the world. Consolidated component volume sourced globally from reliable partners is expected to reduce costs and improve quality as these new products are brought to market over the next two to three years. Hyster-Yale Group’s largest manufacturing facilities in Berea, Craigavon, and Greenville are expected to be structured to reduce costs and improve productivity while most other plants will see more modest changes. China production activities are expected to be consolidated at Hyster-Yale Maximal over the course of 2019.

Hyster-Yale Group currently has over 290 different forklift models in its range which are supported by the ability to customize these trucks to meet specific customer needs. The modular nature of the new products being introduced will enhance the ability to meet exact customer needs at lowest cost, both at the industry level and at the individual customer level. To ensure the full benefit from these programs, Hyster-Yale Group has made a substantial expense investment in its sales and marketing organizations to realign teams around industry groupings. Within marketing, industry-focused resources have been added to develop industry strategies. The higher-priority industry strategies have been completed for North America and Europe. All of the strategies are expected to be completed for all countries, or groups of countries, around the world by the end of 2019 but will mature and be enhanced over future years. To support execution of these industry strategies, Hyster-Yale Group has invested in additional industry-focused sales capabilities to support its dealers. This industry-focused structure has been in place and highly successful in the National Account direct sales program and is now being deployed with the new dealer support teams. These investments are largely in place in North America, and to a lesser degree in EMEA. Additional sales capabilities are expected to be added in other areas around the world over the next two years. In total, the Company believes that these projects will put it in a position to be a leader in the delivery of industry- and customer-focused solutions worldwide.

While the new sales teams will support dealers’ sales efforts, the Company will also continue to upgrade its global dealer capabilities. A core objective is to have dealers that are fully capable of maximizing the potential of the Hyster® and Yale® brands in their territories. These dealers will be supported by a commitment to helping dealers strengthen the excellence of their activities in all areas of their business including leadership, sales, parts, service, rental, leasing and remarketing. To help these programs have maximum impact, the Company will be investing over the next few years in enhanced digital customer experience systems. Taken together, these initiatives amount to a new, uniquely competitive way of serving the markets around the world.

Bolzoni is also pursuing very aggressive projects to expand its global market position. This includes strengthening Bolzoni’s ability to serve the North America market by taking responsibility for Hyster-Yale Group’s Sulligent plant, where it will manufacture attachments and also continue the plant’s support of Hyster-Yale Group through the sale of cylinders and various other components. Bolzoni will phase out production at its current Homewood, Illinois facility, but intends to maintain a distribution center and certain other operations in that area. There is a large opportunity for growth in the North America market. To help capture this, Bolzoni plans to introduce a broader range of locally produced attachments available with shorter lead times to serve its customer base. Bolzoni also has plans to increase its sales, marketing and product support capabilities in North America. In addition, it has developed a standard product line sourced from one of its factories in China, which will continue to be expanded. Bolzoni’s current outstanding premium line of products coupled with these standard products and an industry-focused strategy are expected to give Bolzoni the ability to increase its sales significantly in the Americas, JAPIC and EMEA regions. Bolzoni’s results have been improving on a progressive basis since its acquisition three years ago. These new programs are expected to increase the Company’s market position and profitability, especially over the next three to four years.

Nuvera is approaching the point where it will move from being a venture business focused on commercializing leading technology to a mature, product-based company serving not only the forklift truck market, but also heavy-duty applications such as buses, trucks and applications in the automotive sector with an expanding line of developed products. Nuvera expects its core technology to move to a new generation of fuel cell stack design over the next year with broad application in each of these markets. Quality and cost of fuel cell engines have been improving and are expected to reach target objectives over the next two years. With the transfer of the responsibility for development of non-fuel-cell engine components and the overall assembly of BBRs to Hyster-Yale Group, Nuvera will focus entirely on fuel cell stacks and engines. To enhance its cost base, Nuvera continues to work on standardizing its products, developing lower cost suppliers and automating various elements of stack production. To help sharpen its focus on fuel cell stacks and engines, Nuvera sold its hydrogen-generating PowerTap® business to a third party, OneH2, Inc., in exchange for a note and a minority ownership interest in OneH2. OneH2 has developed an important option for hydrogen fuel supply for forklift truck fuel cell users. In overview, Nuvera’s objective is to reach break-even in both the fourth quarter of 2019 and the full year of 2020, with a move toward target profitability over the following three years.

In summary, Hyster-Yale believes it is approaching an inflection point in its business. While the early part of 2019 is expected to reflect continued investment in all of these programs, the second half of 2019 is expected to be significantly improved in comparison to the second half of 2018. Hyster-Yale Group’s efforts to find offsets to the tariff-driven unprecedented material cost inflation witnessed in 2018 will mature during 2019, and efforts to abate the most critical supplier issues, which are still having an impact on production, are underway with most expected to be resolved by mid-year. The current lift truck backlog contains certain deal-specific pricing agreements at less than target margins to gain targeted accounts and for which margin improvement efforts will take some time to mature. These deals will have an impact on profitability, mainly in the first half of the year. Generally, margins are expected to recover fully from the 2018 material cost inflation and the heavily discounted deals by the third and fourth quarters of 2019. In 2020 and 2021, a considerable portion of the new projects outlined above will have reached completion for all three companies and the Company believes the full impact of these programs can lead to profitability improvements for a number of years to come. Finally, the remainder of the programs are expected to come to fruition in 2022 and 2023, with a few, particularly those involving dealer structure and excellence, being more in the nature of continuous improvement rather than projects which reach maturity at a given time. Of course, the absolute level of profitability will reflect actual market demand levels. The Company is currently forecasting strong but moderating forklift market levels and a resolution to Brexit in a way which does not significantly harm Hyster-Yale’s business prospects.

The Company believes that investors who are focused on mid-term business improvement in market position and profitability will find that Hyster-Yale’s focus is consistent with those investment objectives.