At SMTA Guadalajara, IDENTCO to showcase new Automated Wire Marking System and tout local engineering expertise

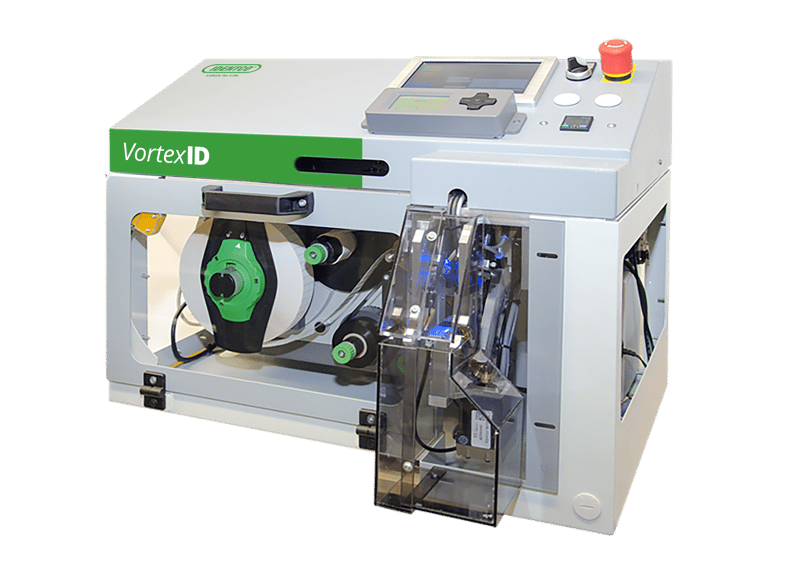

IDENTCO, a manufacturer of high-performance labeling solutions for the power equipment, electronics, transportation and general industrial sectors will feature its rugged new automated wire marking system at SMTA Guadalajara, October 25-26, 2023. At Booth 1214, the company will offer live demonstrations of VortexID, whose stamina and speed raise benchmarks for wire and harness label application. This marks the first time IDENTCO is exhibiting the new solution, which entered the marketplace earlier this year.

In addition, in advance of the show, IDENTCO has announced that one of its longstanding label application engineers, Cesar Ramos, is relocating to the Guadalajara area. The move provides existing and potential customers in the region with even more hands-on, optimized service.

VortexID can precisely place up to 20 labels per minute – outpacing other automated units and doubling the output of even the most efficient manual setups – and operate 24/7, a welcome upgrade from the continuous use limitations of many label applicators. The machine can handle a variety of American wire gauge sizes (AWGs), making is suitable for a broad array of sectors whose products incorporate wires and harnesses – particularly automotive and electronics components manufacturing. It offers high-resolution, 300dpi printing capabilities, with labels applied via a vacuum plate whose rotating mechanism ensures reliable application to cylindrical products.

Notably, IDENTCO’s VortexID is materials agnostic, expanding customer choice and potentially decreasing overall materials costs. The unit can apply both self-laminating and flag labels, an attractive two-for-one modularity accomplished by an interchangeable applicator. This versatility by design is another differentiator, providing customers with a flexible solution that eliminates the need to purchase specific machines for each label type. For both types, the VortexID’s application consistency and repeatability ensure neat, secure labels whose crucial product traceability and electronics testing information must be pristinely printed and unobscured.

Still, the new unit’s robustness may be its most groundbreaking strength. While most automated applicators in its space max out at eight hours of continuous use, VortexID can operate continuously, processing thousands more products per day.

“With demand surging, customer needs for high-volume wire and harness manufacturing continue to rise, prioritizing solutions that automate key processes along the production line – including the labeling process,” said Cesar Ramos, Label Application Engineer for IDENTCO. “We designed the VortexID automated wire marking unit with speed and durability in mind, combining high throughput and continuous operation with precision printing and label placement for long-term information readability.”