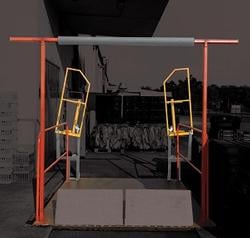

New Dock-Lift safety gate provides automatic safety for employees in loading dock area

For over 30 years, Mezzanine Safeti-Gates has provided dual-gate safety systems used primarily in elevated pallet drop and picking operations. With the new Dock-Lift gate, the company has extended its product line into loading dock operations.

Originally a custom design for a national grocery chain to make their operations safer, the Dock-Lift safety gate is a self-closing gate designed to automatically close and lock into place as the lift elevates, forming a barrier for employees on the lift that make the transition from the tractor trailer to the loading dock or ground level. The gates stay locked until the lift is lowered and back on the ground. The gates automatically open when the platform is on ground level so material can be transferred on and off the lift.

“Our new Dock-Lift safety gate is a great example of the ingenuity of our engineering team,” said Aaron Conway, president of Mezzanine Safeti-Gates, Inc. “Our engineers were able to take a concept from a conversation and turn it into a real, working product for an application in which we hadn’t designed for before, platform and scissor lifts used in loading dock operations. After testing this custom design at the customer’s locations, we determined the design would have wider appeal and decided to put it into production.”

The Dock-Lift safety gate meets OSHA and ANSI codes for work platform lifts and aerial scissors platforms, and are available in powder coated mid steel. The company’s line of dual-gate safety systems provides a controlled access area and maintain a safe environment at all times, ensuring OSHA, IBC and ANSI compliance.

Mezzanine Safeti-Gates was awarded U.S. Patent No. 9630823 for its swinging gate style Dock-Lift safety gate. The patents mark the fifth patent the company has received for its innovative safety gate line; a sixth patent is pending.