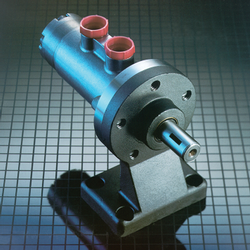

Dayton Lamina- Hydraulic Motors provide four times more torque

Dayton Lamina™ hydraulic motors feature a unique design that allows 4-times more torque to be produced at ¼ the speed without gear reducers, making them ideal for material handling and packaging applications, like conveyor drives and box sealing. With torque ratings comparable to larger motors, they save size, weight and cost over larger similarly rated motors. These low-speed/high-torque, high-speed/low-torque motors feature instant forward and reverse. Six motors are available with a torque range from 0 to 656 in-lbs. and speeds from 0 to 2255 RPM, providing the selectivity required to meet exact project parameters. Four flange options allow fast and easy assembly to other production equipment. Dayton Lamina™ hydraulic motors include a bronze-plated bearing surface, positive metal-to-metal sealing, a positive splined drive and a matched gerotor. In addition to material handling and packaging, these proven models are ideal for a wide range of applications including, hose reel extraction, fan drives, pipe valve openers, undersea tool manipulators, thread core removal for plastic injection molding, camera manipulators in nuclear environments, EDM machines, and more.

With only three moving parts, they provide a longer service life than traditional electric versions. These motors include a main shaft that can be readily adapted by use of chuck or collet to hold tools for rotary machinery operations, such as drilling boring, reaming and other tasks. They perform with flow rates from 1 to 8 GPM to deliver from 100 to 1500 PSI. Parallel circuits are suggested rather than series circuits to keep back pressure below 300 PSI. Products are available worldwide through a network of specialized distributors, with industry-leading deliveries. Service and support provided through Dayton Lamina’s extensive technical support network.