Reduce overhead crane work cycle times with Target Positioning from Konecranes

With the touch of a single button, Target Positioning from Konecranes, the load automatically travels from a staring position to a preset target, slows down, stops and lowers the load at the destination point. It is designed to significantly increase productivity and enhance safety. Often times an overhead crane moves loads from known pick-up positions to known end locations, hence the work cycle is very predictable and repetitive. Traditionally in this pattern, the operator manually moves the loads, which is not the most effective or efficient way. Target Positioning, a smart feature from Konecranes, brings the load from any home position to a defined target position automatically requiring the operator only to push a single button on the operator interface. This feature has been designed to enhance safety and significantly reduces work cycle times.

With Target Positioning from Konecranes, the operator selects the load’s target address and presses the Target Positioning button on the operator interface. As long as the button is pressed, the crane drives itself to the selected target with a preconfigured travel height. The load will navigate to the selected target position (X, Y) at the predefined height (Z) and allow the operator to do the final vertical positioning manually. Manual operation can be always started by releasing the Target Positioning button on the control device.

Target Positioning from Konecranes allows the operator to define up to 120 targets and seven home positions on the crane operator interface or Service Display Unit. The operator interface also has a quick home feature that allows setting a home position for temporary use only by pushing the home button.

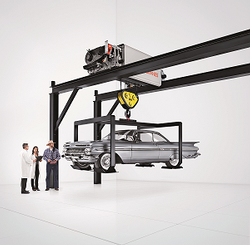

Konecranes’ line of SMARTON cranes is available with Smart Features, software-based intelligence that offers total control over process tasks, saving time and increasing productivity. The Target Positioning Smart Feature improves productivity and safety by adapting the crane’s working area to the physical layout of the production line.